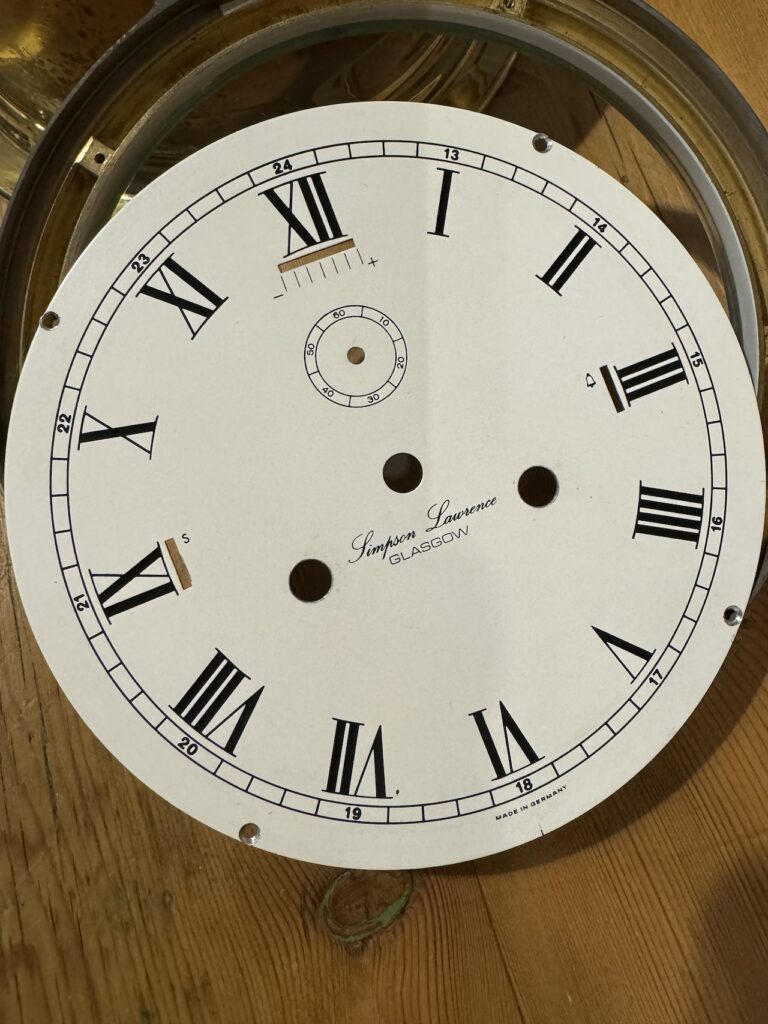

I was delighted to have the chance to repair a noteworthy clock, from the boat house of the Cambridge 99’s rowing club. The clock is a ship’s bulkhead clock, retailed by Simpson Lawrence. It is an example of a decorative clock retailed by a jeweller or department store that used an off-the-shelf movement to keep costs down.

The movement follows a design typical of around the 1970s to 1980s, so was probably manufactured in that period.

The clock uses a German movement made by Urgos in Villigen (no longer trading). It is constructed with modern materials, eg. use of steel C-clips rather than taper pins, but has a fairly traditional brass structure. It uses a traditional two-train movement (time and strike) and is regulated by a jewelled balance platform movement instead of a pendulum, as is correct for use on a boat that would be rocking at sea.

The strikes can be silenced from the front dial, or a one-off bell strike can be triggered to advance the sequence conveniently. The time keeping can also be fine-tuned using a Slow-Fast adjustment lever bar linked to the platform inside. The strike side has two hammers that strike a shell-back bell every 30 minutes and follow a ship’s watch pattern, which repeats every four hours. This is a nice touch.

The time movement (right hand winding hole as seen from the front dial) was slipping around, and unable to hold power. This was due to a fracture failure of the mainspring. Unfortunately, a failure of this type is typically extremely damaging as all of the power in the spring is released into the clock movement in one instant. When this spring failed at some point in the past, had anyone been standing nearby they would have heard a rather loud bang! The clock would have stopped instantly.

The clock was duly disassembled to its parts, and cleaned in the ultrasound bath. All traces of oil and other materials were polished out of the pivot holes. A new Trifix (Swiss) mainspring matching the height, length and thickness (power) of the original was fitted to the barrel on the time side.

The earlier spring failure and associated energy released had bent the arbour of the third wheel of the time side of the clock. This was resolved by straightening the pivots at both ends and refinishing them on the lathe, and then milling fresh holes and fitting bushings to the plates to hold the wheel correctly again.

As the clock was apart, other opportunities for bushing repairs to eliminate wear were also completed (e.g. the second hand which emerges through the front dial is actually directly engaged with the escape wheel of the clock, and had excessive play, which has now been resolved).

When the clock was reassembled, initial tests seemed promising, but the balance movement showed very low amplitude and shortly after starting, the escape wheel staff broke free. My theory is that this was the final victim of the earlier spring failure, having received a shock and either failed through a bent arbour or because of a missing jewel that was dislodged from the spring failure.

The balance platform was replaced, and the clock is now working as expected.

As with most modern movements, Urgos probably intended this clock to last for around 25 or 30 years and then to be replaced with a new movement (which would be fine if they had stayed in business). It is doing ok to make it this far, as it has now been with the club for perhaps 40 years at a guess.